The HSE have published a detailed report (RR1177 - Risk control for small pressure vessels) into the risk/control surrounding “smaller” pressure systems in scope of PSSR 2000 which includes, as a lead, coffee machines.

Contains public sector information licensed under the Open Government Licence v3.0

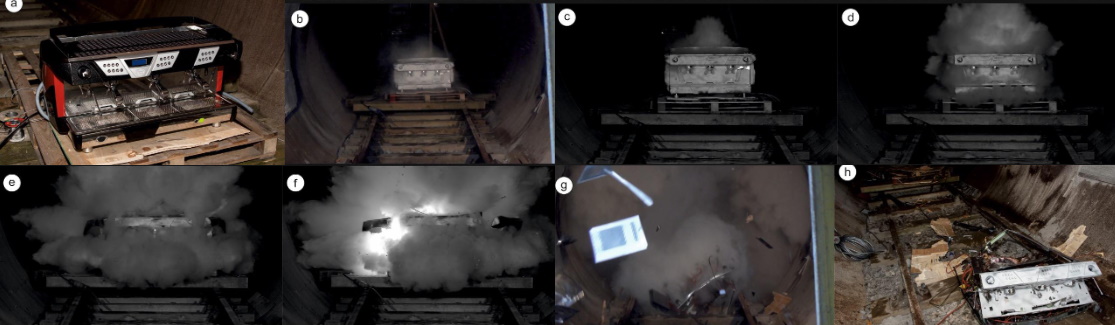

The report is supported by some very extensive investigation work whereby they purchased several coffee machines new and old to better understand their design standard, protective/control circuits and mechanical integrity prior to performing forced over pressurisation of them to the point of explosion.

Their findings and report summary align and support our view and knowledge of this subject, which is that in scope coffee machines if not operated, maintained and examined at set frequencies under a certified WSE have the increased potential to cause serious injury.

The HSE therefore conclude that Pressure System Safety Regulations 2000 must be applied in full to in scope coffee machines in order to reduce the risk via the control measures the Regulations/Approved Code of Practice (ACOP) set out.

They highlight the importance of the requirement of examinations under the WSE and emphasise the need for the protective device/control systems to be included within the WSE and therefore examined as part of the full pressure system examination.Again this is a key factor that we have always stated and insisted on, quite often in contrast to other WSE providers.

Please see some key findings below and the full report attached:

- Twelve coffee machines were examined (both new and second-hand).

- Hazardous defects were noted in the condition of the electrical systems in two of the second-hand café boilers. This highlighted the critical importance that the café boilers’ electrical control systems are examined, tested, and maintained at regular intervals.

- Of the ten relief valves that were tested from the second-hand machines, three did not operate until higher pressures than the relief pressure were applied.

- In eight overpressure tests, the boilers failed at pressures between 18 bar and 28 bar. This was 9 to 14 times higher than the rated pressure on the pressure relief valves.

- In these overpressure tests, five failed catastrophically by ductile overload, fracture and then an energetic release of steam and fragments. The other three boilers all failed by a slow release of steam.

- If a person had been close to a boiler when it failed catastrophically, it is likely they would have been seriously or fatally injured.

- Manufacturing quality has not been implicated as a cause of premature failure during pressure testing.